4WD off-roading – Dana 35 vs Dana 44 axles. The Pros and Cons!

At some time, if you have not already done so, you are going to start looking at your tire choice. However, as you progress in your research for better tires, you will probably realize you can’t just stick on vastly wider or much bigger diameter tires onto your standard factory axle. You will have probably read about differential housings and axle tubes exploding.

Motor manufacturers don’t go much for “over-engineering” their components. Why? Because it costs more! A classic case scenario is a famous Japanese 4×4 brand that around the year 2010, reduced the number of wheel nuts from 6 to 5. That was a purely money-saving feature. It has zero practical use.

But producing 500 000 vehicles a year saves two million wheel studs, wheel nuts and reduces the amount of machining two million times! That is a saving of around 10 million dollars! So expect that your stock standard axles are just sufficient to do the job required.

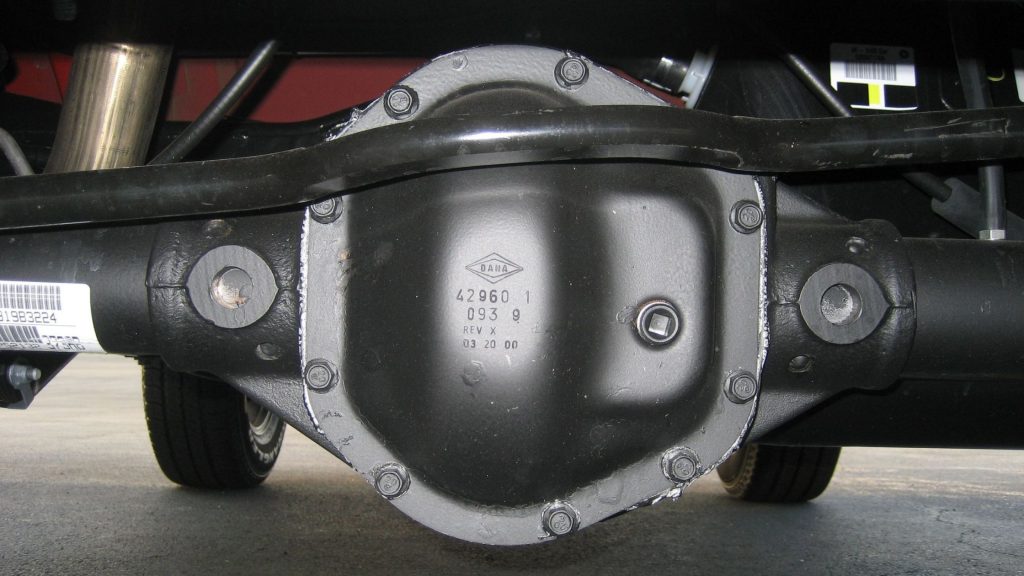

However, the good news is that there are many after market manufacturers of axles, and Dana is very high on the list of outstanding drive train complete axles and drive train components.

They make specific axles for Chevrolet, Dodge, Ford, Land Rover, and Jeep in a large variety of ratios.

Actually, you can retrofit a Dana axle to virtually any vehicle. They specifically sell such bare-bones axles.

The Dana 44 axles extend their usability to Nissan, Mitsubishi, Isuzu, General Motors, Pontiac, and it has even crossed the ocean and was used in Jaguars and Volvo!

DANA 35

The Dana 35 produced a number of ratios, many of which are still available.

| Ratio:1 | Pinion:Ring Teeth |

| 2.21 | 19:42 |

| 2.35 | 17:40 |

| 2.37 | 19:45 |

| 2.53 | 17:43 |

| 2.73 | 15:41 |

| 3.07 | 14:43 |

| 3.08 | 13:40 |

| 3.31 | 13:43 |

| 3.54 | 13:46 |

| 3.58 | 12:43 |

Ratios are used to regulate the number of rotations the wheel makes in relation to the main propeller shaft or pinion shaft.

So the Dana ratio of 19:42 really means the wheel rotates slowly and the propeller shaft rotates faster. The engine also revs higher to achieve speed. To further explain this, it means you get the maximum torque delivered to your wheels but slower speed.

This would work well in a commercial farm or delivery vehicle.

A ratio of 12:43 will give you slower engine speed, slower propeller rotation but high-speed tire rotation with less torque. Probably best suited for racing.

Pros

It is available in both fixed axles and independent suspension axles in a range of ratios from 3.07:1 to 4.88:1 for the TTB axle and ratios of 3.08:1 to 5.13:1 for the IFS.

This axle has a long history. Many off-road drivers say they are fine if you look after your vehicle. In other words, drive responsibly. Don’t drop the clutch or change gear midway up a steep rocky climb.

Cons

I’ve heard the expression on a number of forums that it is not “dummy proof.”

The axle tubes are light and are known to break and bend. Many off-road drivers beef up their tubes by welding on ribbing. That works fine but is a bit of a specialized modification because you have the possibility of heat distortion.

The Dana 35 can best be described as a good axle for general driving or off-roading but has significant weaknesses if worked hard. Without some reinforcing, it is not really going to stand up to rugged off-road driving.

It also has a significantly smaller and less rugged differential and side shafts.

Just to examine the rear axle:

⦁ In our opinion, the big weakness is the small 7.5-inch ring gear, about the size of a large cell phone. This means a tiny pinion shaft gear, which also has a record of breaking during off-road driving.

⦁ The axle shaft diameter is a mere 1.09 inches (28mm). Breakages are common. Many heavy 4×4 vehicles such as Toyota Land Cruisers have 40mm or bigger side shafts and have significantly heavier and more numerous splines.

⦁ It drives through 30 splines.

⦁ The inner shaft spline count is only 27 allowing only around a one-inch shaft. They have been known to break or strip splines.

⦁ There are only 26 pinion shaft splines.

⦁ More splines and deeper splines are found in competitor axles, which last longer.

DANA 44

Also named the Dana 44 ICA and Dana 44 IRS.

We can say the Dana 44 evolved from the Dana 45, which is no longer manufactured.

Here are the improved specifications:

⦁ The front axle ring gear is much bigger, being 8.5 inches or 216 mm.

⦁ The rear axle ring gear is 8.9 inches or 226 mm.

⦁ It covers all the OEM axle spline counts from 10, 19, 29, 32, 33, and 35.

⦁ A wide range of gear ratios from 2.72:1 all the way through to 5.89:1 giving off-roaders a big range of torques to play around with.

⦁ Pinion shaft diameter 1.12 inch with 26, 24, and 10 spline count range.

⦁ A variety of side shaft diameters all much beefier than the Dana 35. These are 1.175 inch, 1.20 inch, 1.30 inch, 1.31 inch, and 1.41 inch. These have spline ranges of 10, 19, 30, and 32 to suit different applications.

The Dana 44 is much more rugged than the Dana 35. There are no flimsy axle tubes. Instead, the axle is a beam type with a short tube on the passenger side.

The axle “floats” or is independent by means of rugged universal joints. Dana produced an axle for Ford that used locking hubs and based the design on the Ford twin beam design for Fords and other models of 2WD trucks and SUV’s.

The Dana semi-floating rear axle has been around since mid-1940’s. It is still in use today because it is simply awesome! It bears 3500 lb or 1600kg.

The semi-floating axle features at the end of each axle shaft and carries the weight of the vehicle very close to this bearing—a big plus in avoiding breakages.

As mentioned, the rear axle ring gear is a big 8.9 inch or 226mm. Appropriately the pinion gear is also bigger and more rugged, with fewer breakages.

This ring gear and pinion have been finely machined and engineered to provide a better gear meshing contact and patch and angle. This helps reduce breakage, reduce the backlash tolerances required, and results in a very much quieter differential.

These are the axles used extensively in many two-wheel drive Isuzu, Nissan, and the Jeep JK’s trucks and SUV’s

Final Review: Dana 35 versus Dana 44

It depends on what you want. But if you are an off-road driver or using your vehicle in a farming or outdoor setting, or want a silky quiet and rugged axle without any doubts, I think we can clearly see that the Dana 44 is superior.

⦁ It has a more rugged construction with Beam type axle as opposed to the tubes of the Dana 35

⦁ It features a bigger crown wheel and pinion, reducing gear crashes and breakage.

⦁ It is relatively quieter.

⦁ They are designed to fit a wide range of Automotive Manufacturers.

Some Q&A

⦁ Can I fit this axle myself?

Yes, any reasonably competent home mechanic with a full set of mechanical tools and 4 axle stands should be able to do this in his garage over two weekends if you are fitting two axles.

⦁ What oil should I use in my Dana axle?

85-140W, Non-Synthetic, GL5 grade or higher, name brand oil. AMSOIL Severe Gear Synthetic is used by many competition off-road race cars.

However, for most off-roaders, look for a multi-grade axle oil such as Red Line 57905 75W90 GL-5 Gear Oil for colder climates and something like Castrol Axle Limited Slip Oil 80W-90 for all other climates and general conditions.

⦁ Are parts available if something breaks?

Yes. All OEM parts are available from Dana direct and are the best choice. Most major online store carries Dana parts.

⦁ What is the advantage of using Dana axles over other brands?

Dana has probably been around the longest, nearly 60 years, and has constantly put a lot of work into its huge R&D department.

You are getting decades of testing and improvement. They have a reputation to protect, and competition is intense, so they don’t skimp in steel or bearing quality.

- Tips and tricks For Setting Up Camp Like a Pro - September 11, 2023

- The Best Multi-Tools for Overlanding Adventures - August 25, 2023

- Off-Road Navigation Tips for Overlanders - August 13, 2023